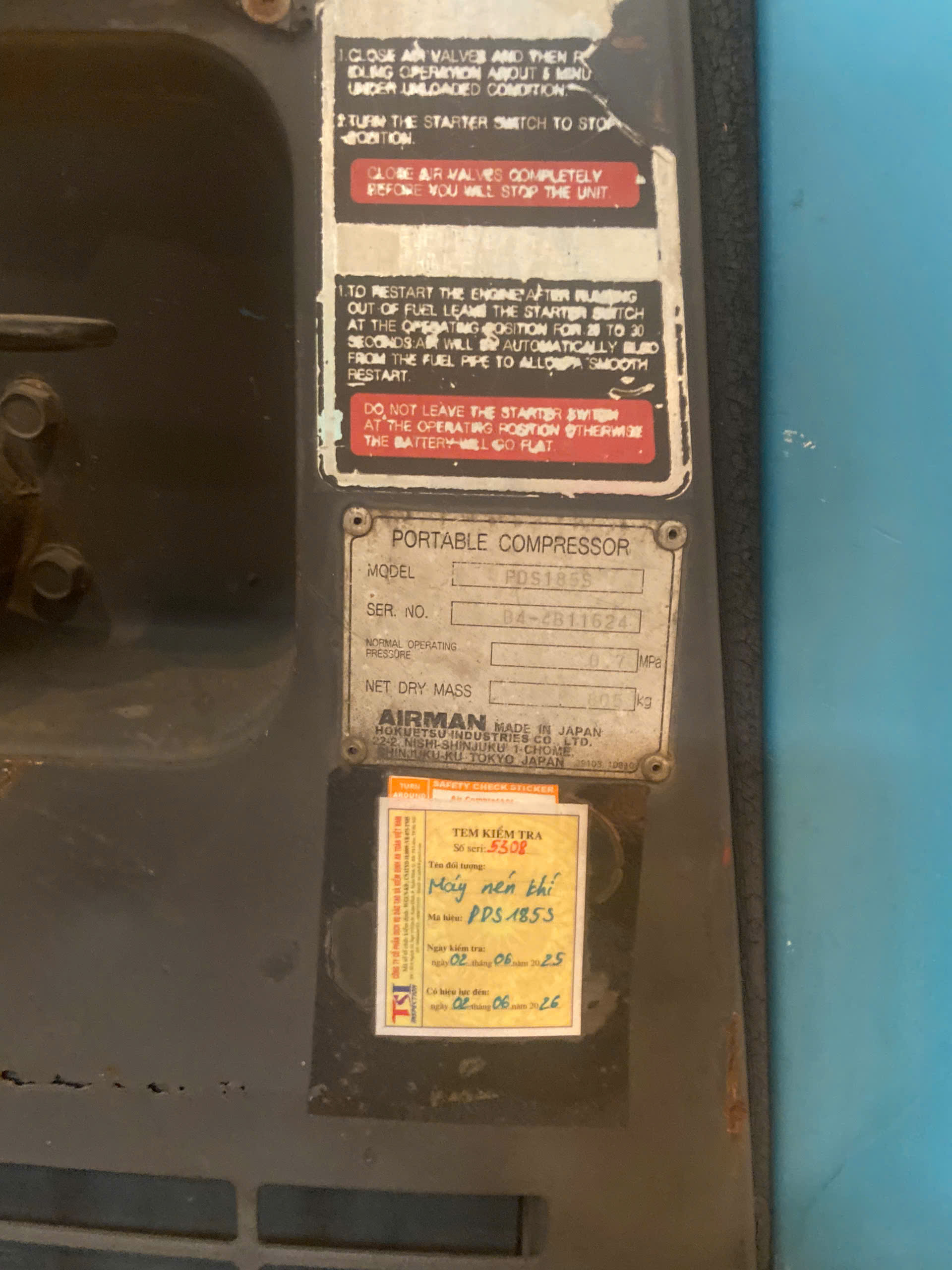

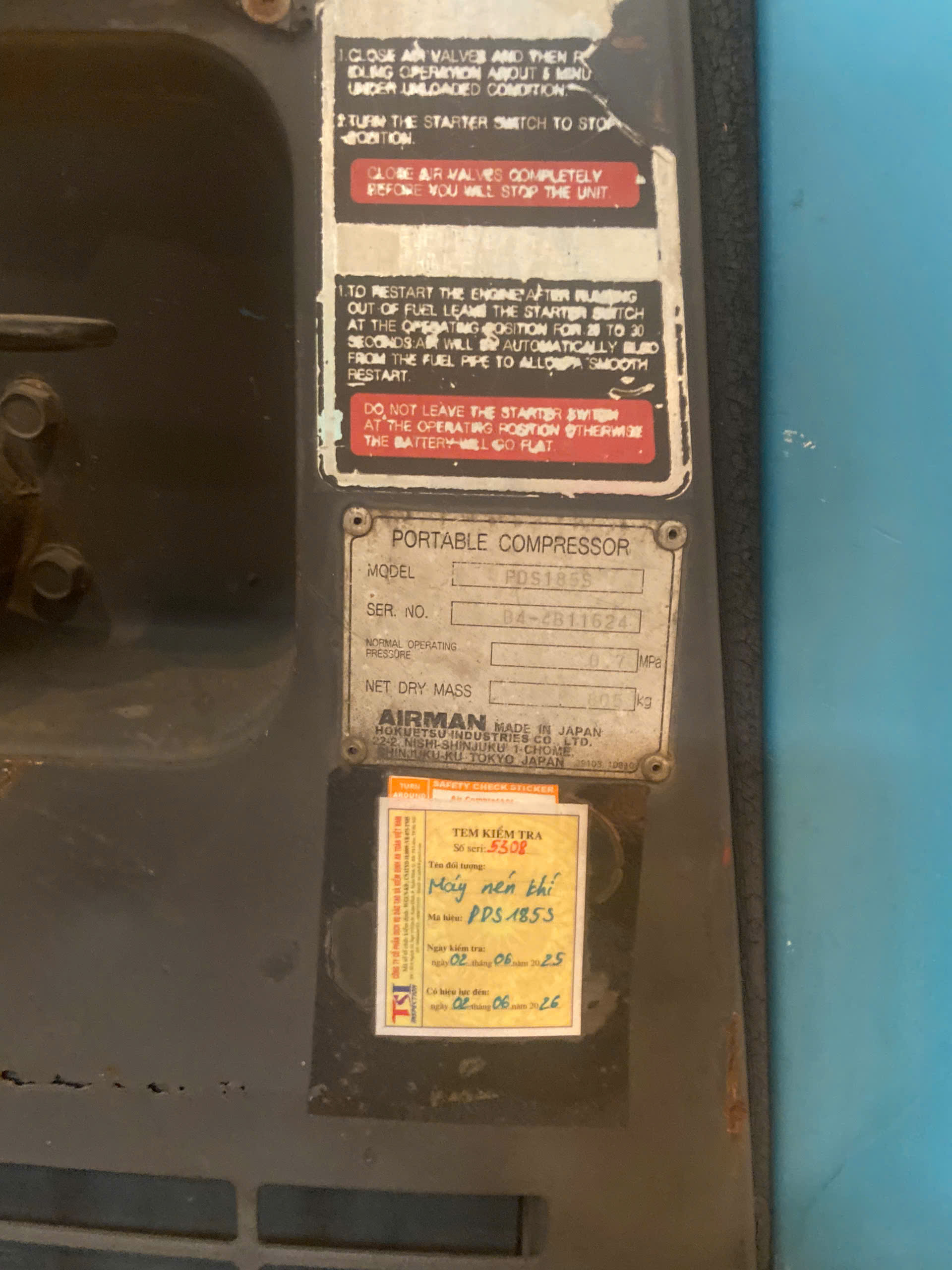

USED PORTABLE AIR COMPRESSOR AIRMAN PDS185S

- Model

- PDS185S

- Type

- Diesel Engine

- Year

- 2007

- Country

- Japan

- Free air delivery

- 5,2 m³/min

- Rated operating pressure

- 7 bar

- Price

- 12x,xxx,xxx VND

- Quantity

- 1

AIRMAN Air Compressors are manufactured by AIRMAN Corporation, a Japanese brand founded in 1938 that has long established its leading position in mobile compressor technology both in Japan and in many markets worldwide. With nearly 30 years of presence in the ASEAN region through a well-developed distribution network, AIRMAN compressors are highly recognized for their exceptional quality, proven durability, and cost-efficient performance. As demand for construction and infrastructure equipment continues to grow rapidly across ASEAN, AIRMAN is further expanding its footprint and strengthening its market presence with high-performance rotary screw compressor models designed to meet the rigorous requirements of modern industrial and construction applications.

This equipment has many different models,

for more details please contact us.

Overview of AIRMAN PDS Air Compressors

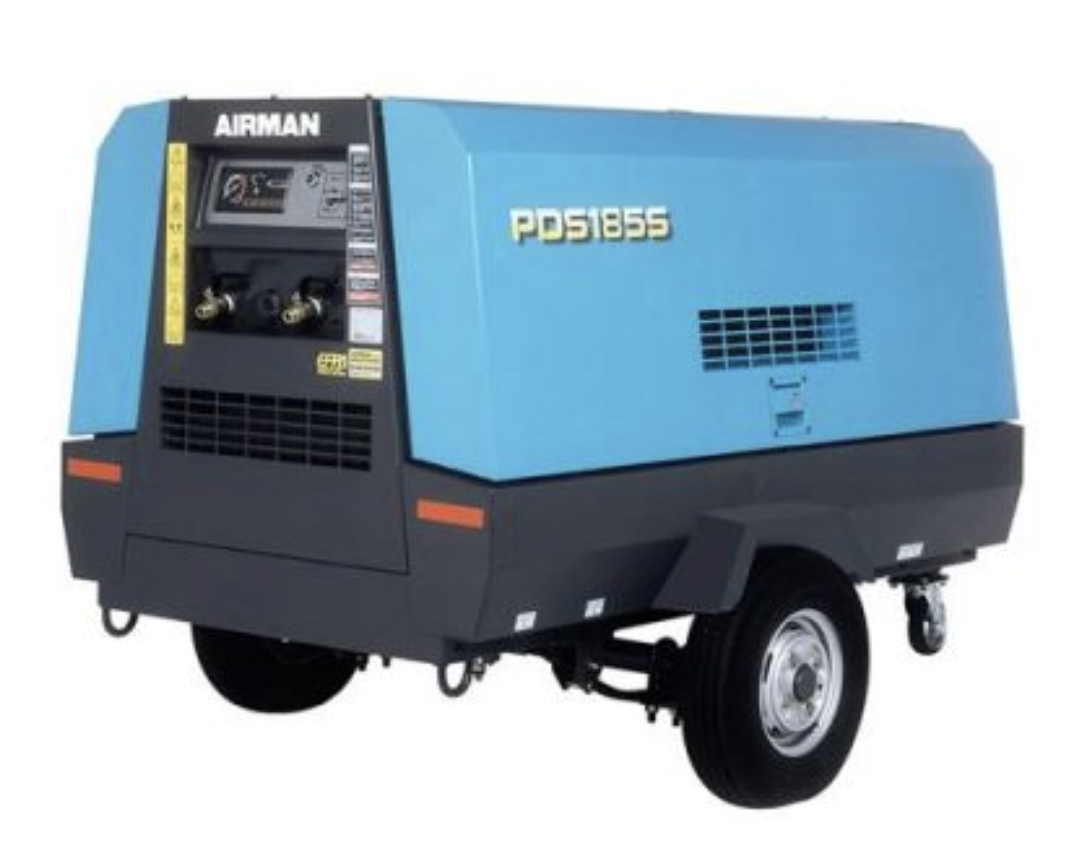

The AIRMAN PDS Series is one of the most widely used air compressor lines at construction sites. This series features a certified soundproof design that ensures low-noise operation, along with user-friendly controls, a monitoring display, and an emergency stop function. In addition, these high-performance compressors have been proven in real-world applications to be both durable and fuel-efficient.

Unique screw design

Specially heat-treated rotors are machined to extremely tight tolerances by utilizing the latest in computer-controlled machinery.

Pro environment (noise)

AIRMAN compressors are designed with original high sound-proof technology in response to market demand for decreasing noise levels.

Pro environment (emission)

The efficiency of the AIRMAN unique profile means that the required engine power is extremely low, resulting in less emission into the atmosphere.

To allow the engine to warm up under a light load, AIRMAN compressors are fitted with a device that prevents pressure from building up in the receiver while maintaining the engine at idle speed.

Capacity control

Automatically adjusts capacity from 0–100%. The control design eliminates engine surging by optimizing engine speed at reduced capacity demands, thus reducing wear and maximizing fuel efficiency.

Operational panel

The panel, fitted at the rear for added operator protection, monitors the machine’s operations.

Serviceability

To minimize service time, AIRMAN compressors are fitted with wide-opening doors that provide full access for servicing and routine maintenance. To further simplify servicing, all drainage points are fitted with valves and piped to the outside of the unit. The fuel system of some models is equipped with an automatic air bleeder.

Tough metal construction

Pre-painting of the full chassis and bodywork prior to assembly with an electrostatic process ensures a tough, high-quality finish and eliminates unpainted, rust-prone metal-to-metal contact areas.

Shutdown and protection system

AIRMAN compressors are constantly monitored and protected against high discharged air temperature, high coolant temperature, low engine oil pressure, and other critical operating conditions.

Operator protection

Fan belt covers and an over-pressure relief valve are provided to offer additional operator protection.

Key strengths and advantages of the Airman PDS185S

- Mobility and flexibility: PDS185S is equipped with wheels and a towable frame, making it easy to move between job sites and across different types of terrain.

- Stable and powerful air output: With a discharge flow of 5.2 m³/min and approximately 7 bar pressure, it is suitable for operating large pneumatic tools such as rock drills, concrete drills, nail guns, breakers, and grout/sand spraying equipment.

- Powerful, fuel-efficient diesel engine: Ideal for environments without electricity—such as construction sites, mining areas, quarries, or tunnels—providing reliable performance and reduced fuel consumption.

- Durable and easy to maintain: Its “gull-wing” design (side-opening panels) allows for convenient inspection and maintenance. Filters, drain valves, and pressure-control components are arranged to minimize service time and maintenance costs.

- Versatile applications: Can be used for geotechnical drilling, foundation work, construction operations, grout injection, sandblasting, cooling, air blowing, and more. It is suitable for various industries, including construction, mining, shipbuilding, and oil & gas.

Practical applications of the Airman PDS185S

With its specifications and performance characteristics, the PDS185S is highly suitable for the following tasks:

- Construction and civil works: Rock drilling, ground drilling, piling support, grout injection, sandblasting, paint spraying, concrete breaking, and powering heavy pneumatic or hydraulic tools, including large handheld drills.

- Equipment rental operations: Thanks to its mobility, ease of operation, and stable air output, the PDS185S is an excellent addition to rental fleets—easy to transport to job sites and quick to maintain.

- Mining and geological exploration: Ideal for locations without a power supply. The diesel engine enables continuous operation in remote or off-grid environments.

- Heavy industry, shipbuilding, oil & gas, and tunneling: Provides reliable compressed air for sandblasting equipment, pipeline pressure testing, surface cleaning, and powering industrial pneumatic machinery.

Advantages of purchasing a used AIRMAN Air Compressor PDS185S from NISHIO

-

Genuine product with complete documentation.

-

Save 40–60% compared to a brand-new machine.

-

Available in stock and ready to use immediately.

-

Dedicated technical support.

-

A reputable scissor lift brand with easily replaceable spare parts.

Please contact us for more detailed information.

※The table can be viewed by scrolling left and right.ecification

Type

Rotary Twin Screw, Single-Stage, Oil-cooled

Free air delivery

5,2 m³/min

Rated operating pressure

7 bar

Compressor oil capacity

15 l

Engine

YANMAR (Make); 4TNV88-8DHKS1 (Model)

Engine type

4Cycle, water-cooled, direct-injection

Cylinder

4

Rated output

36.4(49.5)/3000 - kW(PS)/min⁻¹

Fuel tank capacity

90 L

Engine oil capacity

7.4 L

Battery

85D26R×1

Dimensions (Length x Width x Height)

2960 x 1650 x 1510 cm

Dry weight

860 kg

Operating weight

960 kg

Tire size

175/80R13 97/95N×2W

Sound power level in decibels

98 (dB)

Sound pressure level

72 dB (A)

Designated emissions regulation

US Tier 4